Oil / cooling water temperature monitoring

Increase operational reliability and prevent breakdowns – automatically!

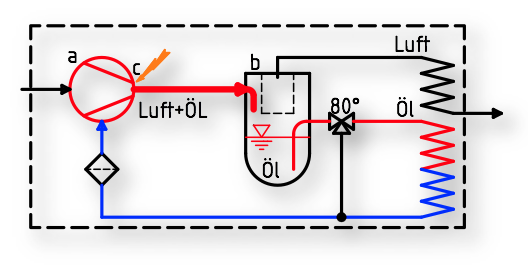

The oil cooling circuit of a compressor

a: compressor stage

b: oil separator

c: outlet compressed air-oil mixture = hottest point of the compressor

80% of all compressor malfunctions are cooling related!

The main reasons are:

- Poor ventilation of the compressor room

- Supply air filter mats clogged with autumn leaves, paper, etc.

- Compressor oil coolers are dirty

- on the oil side due to deposits, coking

- on the air side due to dust and buildup

- On the water side due to calcification or similar.

- Insufficiently dimensioned supply/exhaust air ducts.

- Fan too weak.

- Too little or the wrong oil in the compressor

- cooling water circuit is not working properly

The result

The final compression temperature increases. The compressor works under increased operating temperatures, the oil ages faster, the deposits in the oil circuit (bearings) increase and the wear in the compressor increases. A vicious circle, which in turn leads to further increases in temperature.

The normal operating oil temperature of a screw compressor is between 70 and 80°C.

The accident prevention regulation stipulates a safety shutdown at the latest at 120°C final compression temperature: The compressor is shut down due to excess temperature and goes into "malfunction".

By then, however, considerable damage to the compressor may already have occurred. If there are no reserve compressors, the pressure drops during operation and production disruptions occur.

Solution

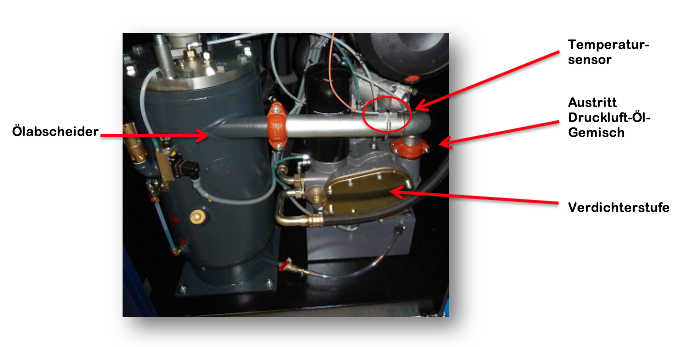

A temperature sensor directly at the outlet of the compressor stage. (The sensor prescribed by law is manufacturer-specific and connected directly to the compressor controller - it is not easy to pick up the temperature!) The Airleader solution, on the other hand, can be used anywhere, is easy to install and is based on industry standards. The measuring range and the output characteristics are specially tailored to the intended use and the airleader electronics.

The airleader connection module for the compressors has an input (AE2) for this as standard. The temperature monitoring is connected here, which is permanently monitored and archived via the web visualization.

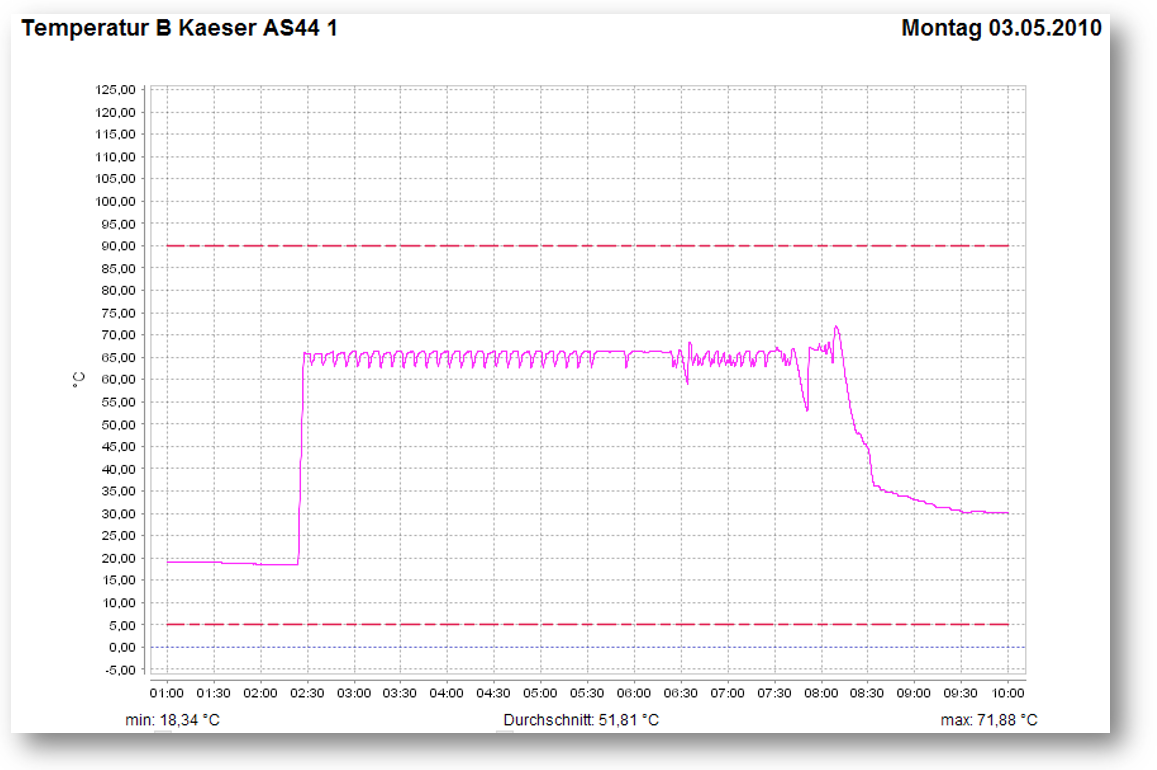

With individually adjustable limit temperatures (e.g. 90°C). When exceeded you receive an entry in the error report of the Airleader visualization, a switching output is optionally set and an SMS or E -Mail sent to react in time and investigate the cause before harmful temperatures occur.

On a compressor failure, the graphic recording of the temperature curve often allows conclusions to be drawn about the behavior before the accident and certain causes can be excluded or localized.

Oil-free compressors

Oil-free compressors are special: as dry-running compressors, they are almost always at least two-stage and water-cooled. There is no internal oil cooling. Here the best indicator is the cooling water outlet temperatureto identify and eliminate the causes of faults in good time.

WF Steuerungstechnik GmbH

Zeppelinstraße 7-9

75446 Wiernsheim

| Telefon | +49 (0) 7044 911 100 |

| Fax | +49 (0) 7044 5717 |

| info@airleader.de |