Differential pressure monitoring in compressed air systems

ΔP-minimization through timely element change saves energy and filter costs

Filters ...

- are only expensive resistances from an energetic point of view

- should be avoided if possible - only as much as necessary-

- differential pressure on the central filter is to be monitored

Differential pressure monitoring on filters with Airleader

Example

filter dimension: 2 “ - Filter (DN 50)

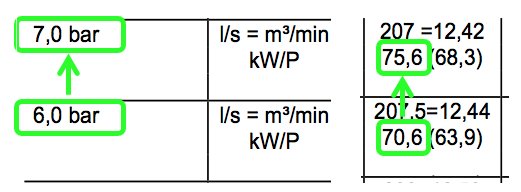

Too much pressure loss Δp on the filter: 0.25 bar (0.35 instead of 0.10 bar)

Flow rate through the filter: 4 million m³/a (≈ 75 kW compressor, 6,000 operating hours/a)

Additional energy consumption of the compressor (manufacturer data sheet):

=> 5 kW additional consumption per bar higher compression

= 5 kW x 0.25 x 5,437 Lh x 0.2 €/kWh

= € 1,360.- every year

More - Energy costs per year: € 1,360 due to too much pressure loss!

Filter element costs for 2" filters: € 200

Excessive differential pressure is recognized by airleader and reported automatically

Requirements:

- airleader MASTER Modul

- Free analog input on the MASTER module or on the RS485 connection module

- Differential pressure transmitter Order no.: DP-1025(< € 500/piece)

Installation example: filter differential pressure sensor on MASTER module

WF Steuerungstechnik GmbH

Zeppelinstraße 7-9

75446 Wiernsheim

| Telefon | +49 (0) 7044 911 100 |

| Fax | +49 (0) 7044 5717 |

| info@airleader.de |