Manufacturer-independent efficiency analysis of compressed air systems

The measurement: Simple - inexpensive - effective!

(Note: If you already have an AIRLEADER, you you don't need the measurement - See simulation)

How much are the savings?

We do!

The measurements possible for this are in detail:

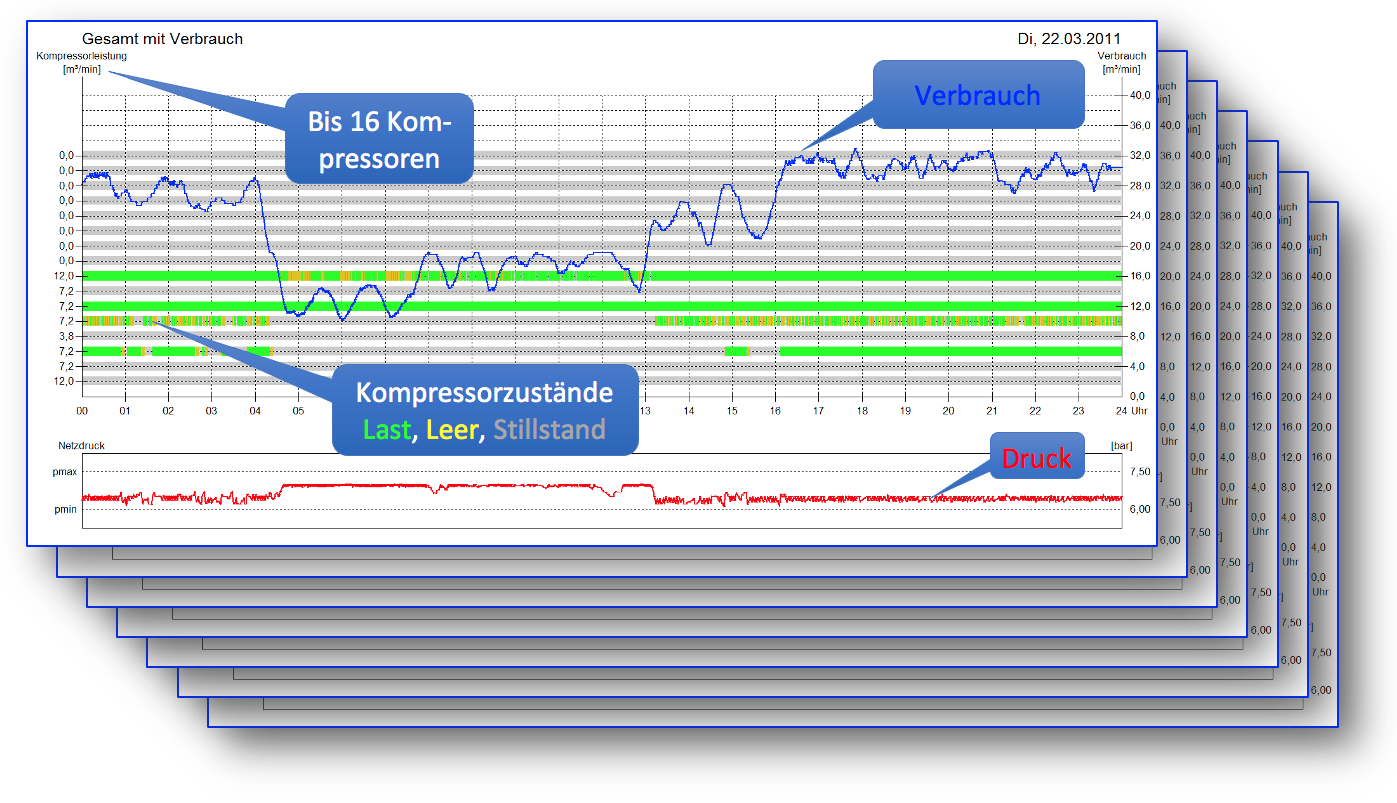

Power measurement on all compressors simultaneously with ampère clamps for determining:

- compressed air consumption profile of each station and

- total leakage air consumption (when all consumers are shut down)

- Energy consumption

- Load and idle compressor times

- Last-hours

- Idle-hours

- Number of motor starts

Temperature trend measurement for determining and checking:

- intake temperature

- dryer installation conditions

- air inlet temperature separate dryer

- incoming and outgoing air

Pressure trend measurement for the determination of:

- pressure profile on site

- Pressure level

- Number of switching cycles

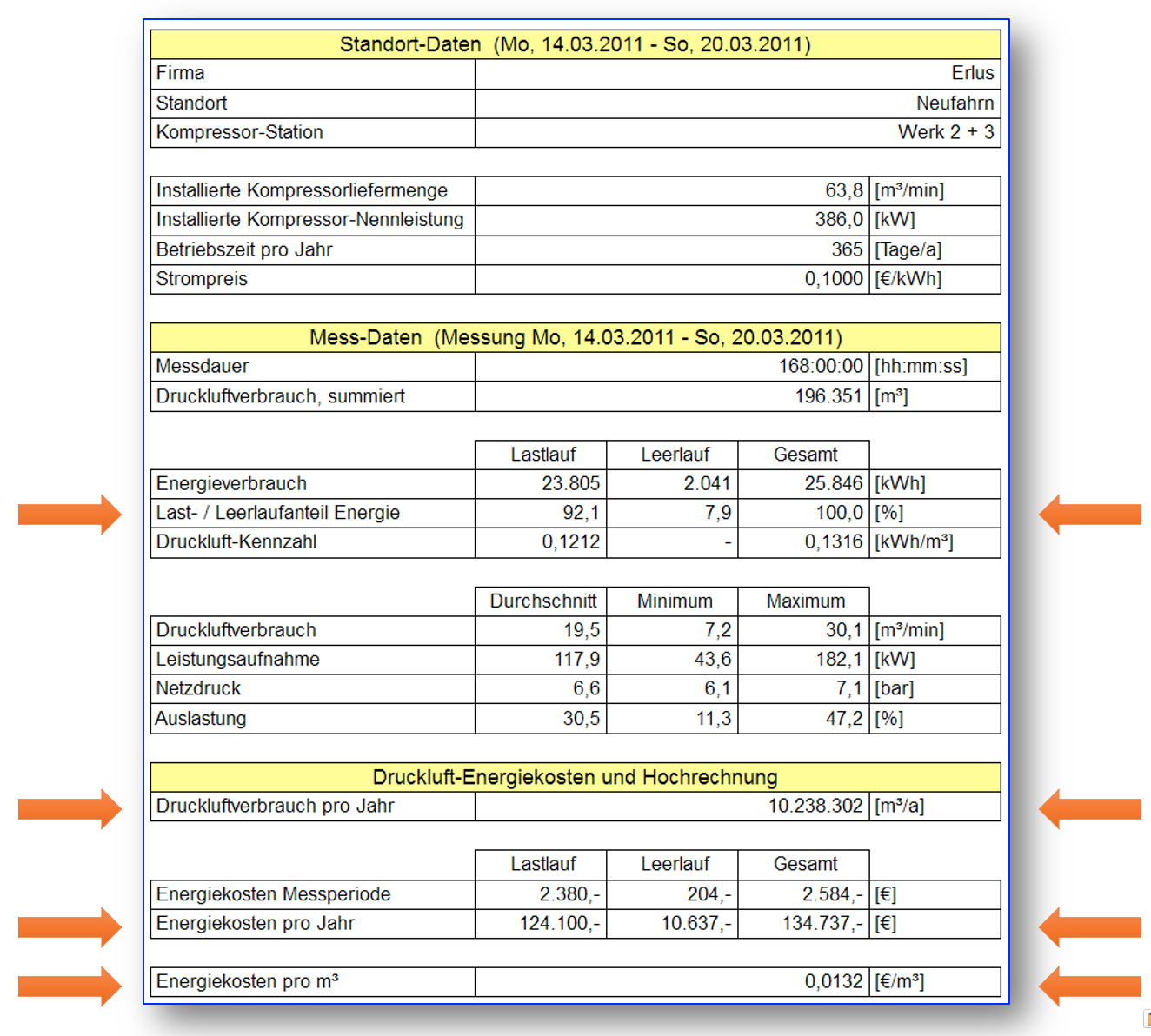

- Efficiency of compressed air generation (specific power, compressed air ratio)

- Supply reliability (sufficient compressors)

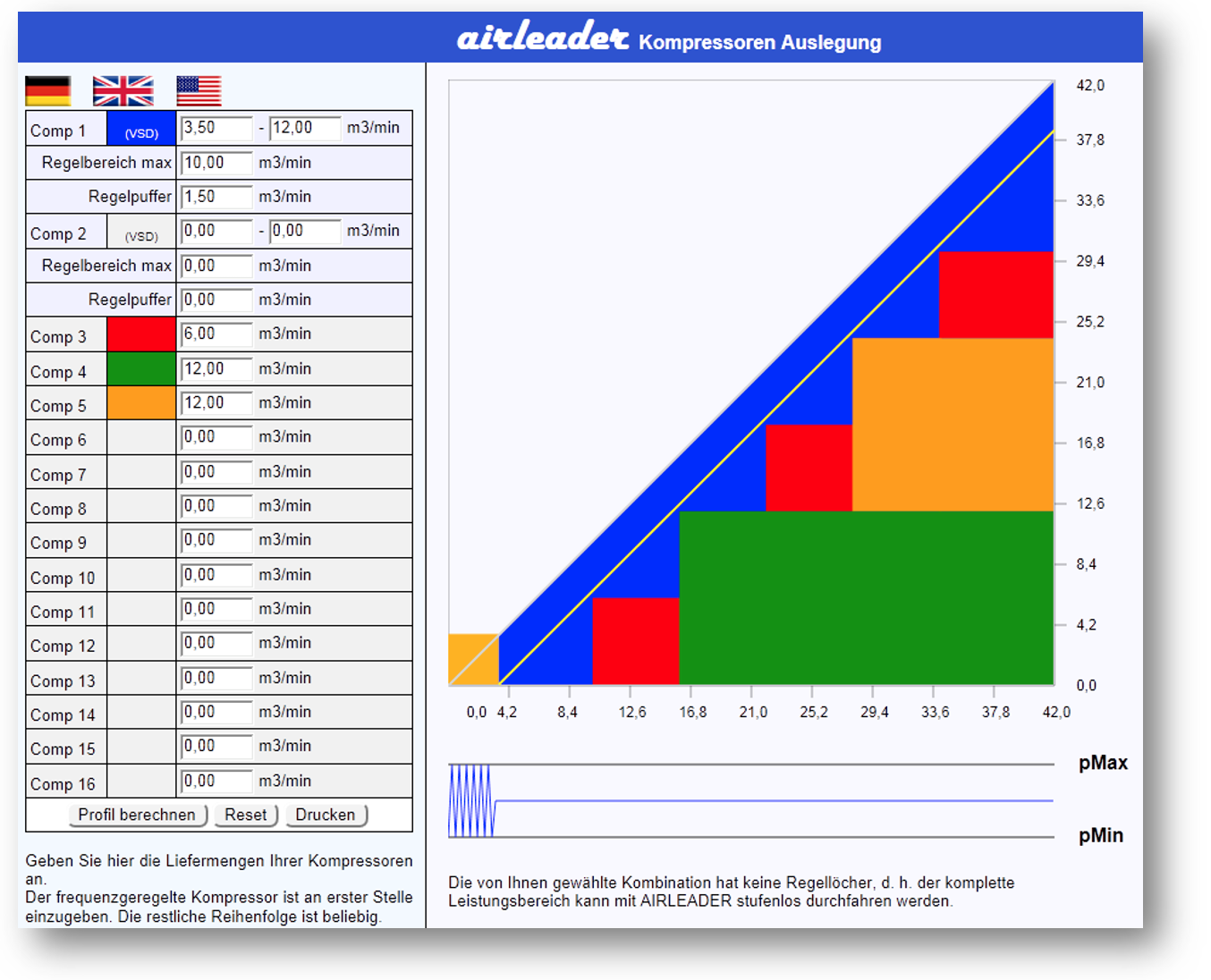

- Dimension/type of new compressors

- Reasonable system splitting

- Savings in airleader use

- Pressure spread

- Differential pressure via air conditioning

Dew point trend measurement for the determination of:

- Dryer function

- Pressure air humidity content

Measuring period: at least 1 week continuous, measurement resolution: 1 second

Measurement report printed and as PDF:

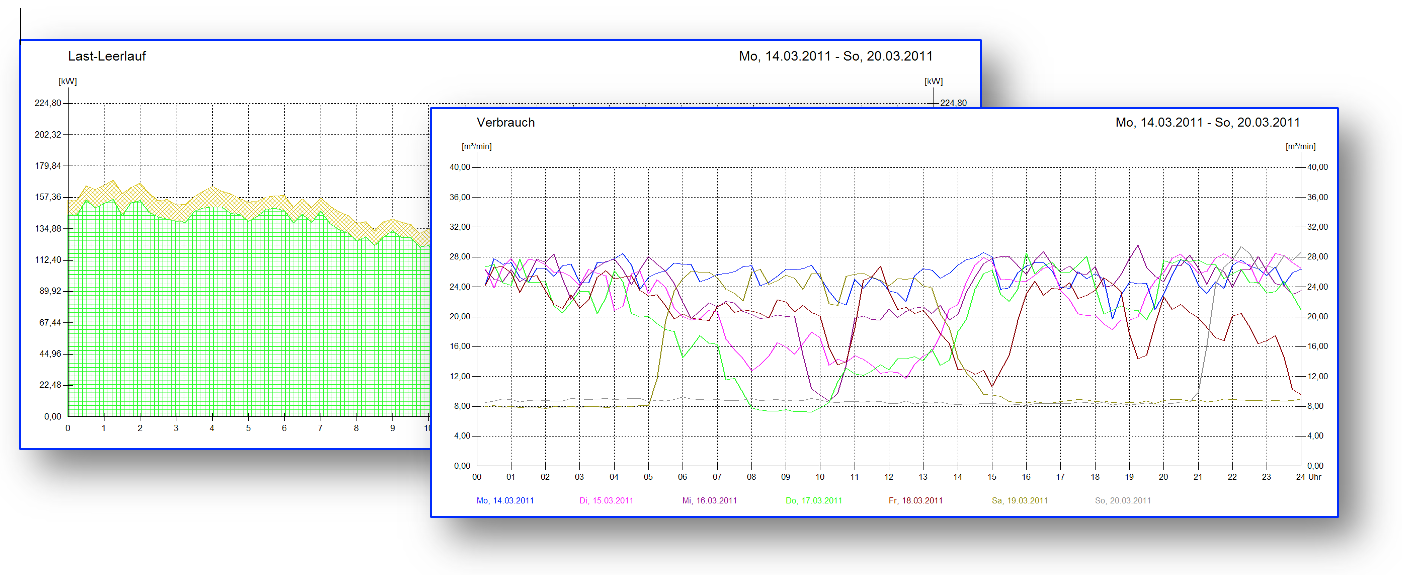

7 x daily evaluation:

Weekly diagrams:

energy splitting load-unload dayli consumptions overlay

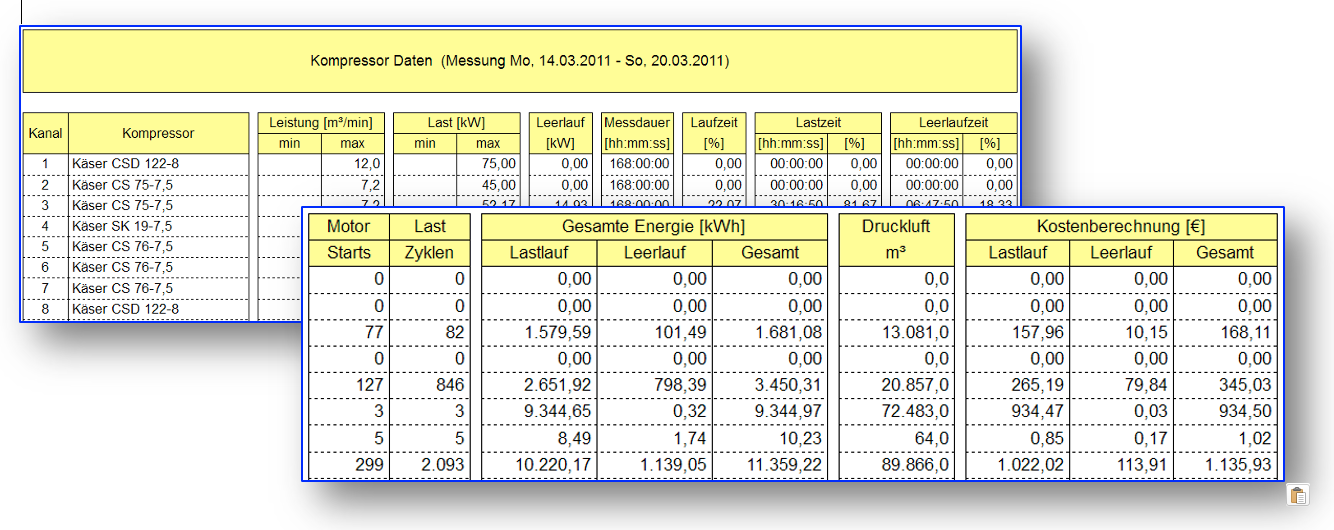

Individual result compressors:

Actual state of compressed air generation:

The simulation - what if ...:

With the data from the airleader measurement, or directly from an existing Airleader *, a simulation can be carried out to ensure the profitability of planned investments, e.g. B.:

- Existing compressors with airleader compressor management

- Existing compressors with new compressor (s) and airleader compressor management

- Complete new installation with airleader compressor management

- Any mix of existing and new compressors with airleader

This makes the future control behavior of the station just as visible as the savings that can be achieved. With an AIRLEADER procurement, we guarantee the savings - otherwise we will take the Airleader back for a refund!

* Note:

If you have an Airleader in use, you can save yourself the measurement: the data can be archived with a click of the mouse (like: see here) and can be sent to us by email.

Service: We charge 298, - per simulation and week